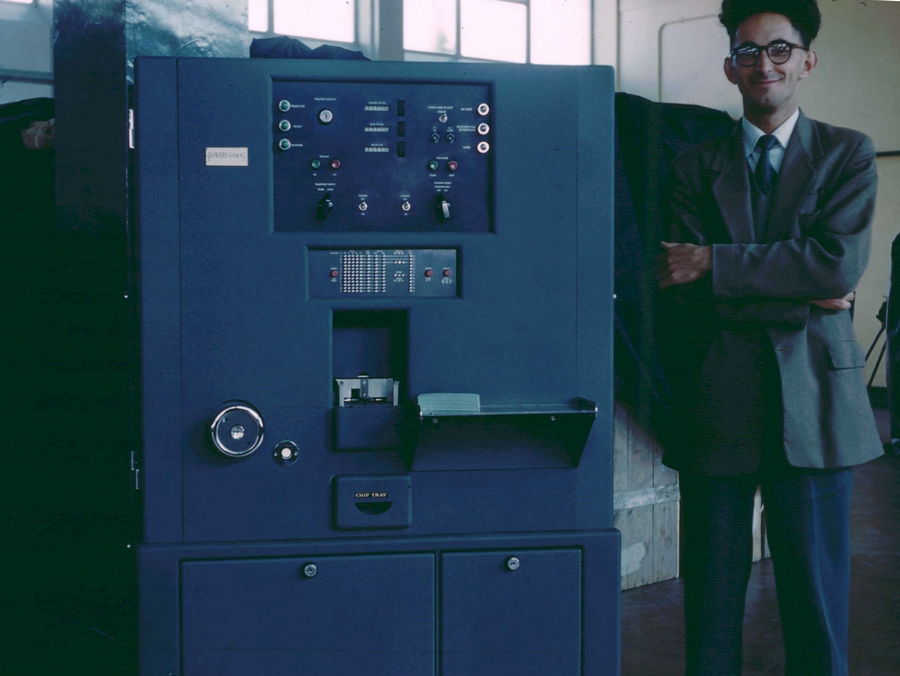

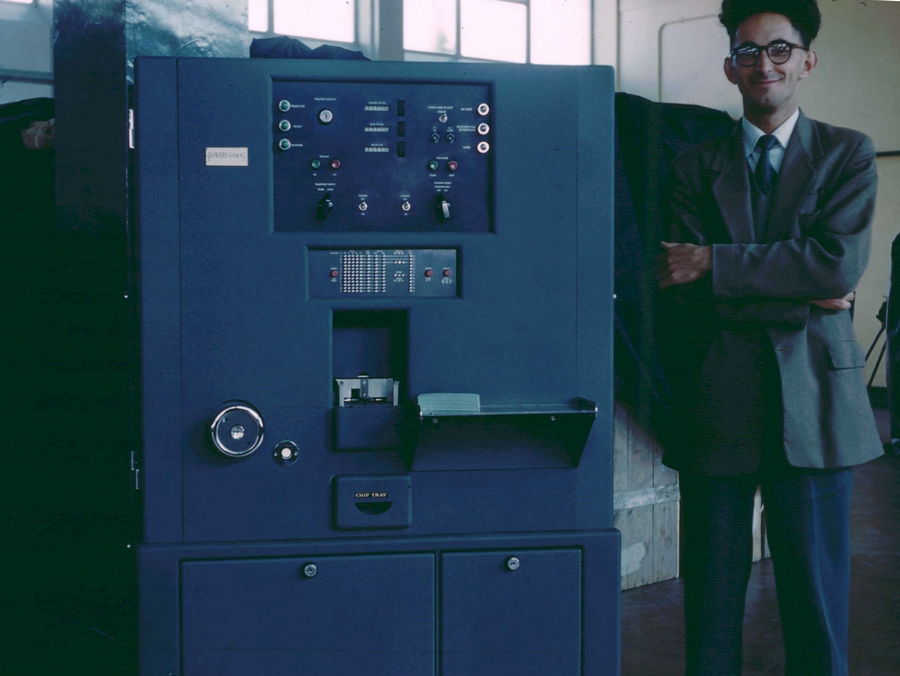

As you can see, this machine constituted a grey box under six feet high, about four feet across and a yard deep. In the middle of the front was the magazine, and a small shelf for 'knocking-up' the cards. Below that the handle of the 'Chip tray' and above was the panel for setting in the fixed data. This was an array of little chromium buttons which had to be pushed in using a metal stylus for the date and the exchange code number. Only the cards for one exchange would be punched at one time, then the new code number had to be set in before the next batch of cards was loaded. There were three odometer counters at the top, one counting the grand total of card passages, one for sub totals and one for the rejects. A round handwheel was provided for rotating the mechanism during servicing or "Wreck removal".

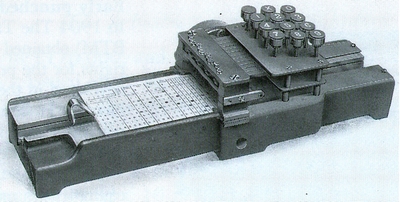

Besides continually reloading the magazine the operator had to correct the rejects. Each reject card had to be scrutinised to determine the cause. Frequently it was due to bad marking by the switchboard operator. One could usually see what she had meant, but if her marks were too far out of position, too small or too faint, the scanner would miss them. Then the machine operator had to put the offending card in her  hand punch and punch in the missing hole. Sometimes the machine had punched extra unwanted holes, possibly due to flecks in the card material or the switchboard operator's marks could be too large, intruding into the neighbouring column. In that case the operator covered the unwanted hole with a little circle of red sellotape applied by means of the 'Winkle's Eye' machine. On a bad day an operator might have to correct hundreds of such cards out of the 30,000 passing through her machine. Any Exchange regularly producing badly marked cards would receive the polite but icy wrath of Miss Whitehead together with an invitation for the Exchange Supervisor to visit the MATS Unit to see the additional work the badly marked cards could produce.

hand punch and punch in the missing hole. Sometimes the machine had punched extra unwanted holes, possibly due to flecks in the card material or the switchboard operator's marks could be too large, intruding into the neighbouring column. In that case the operator covered the unwanted hole with a little circle of red sellotape applied by means of the 'Winkle's Eye' machine. On a bad day an operator might have to correct hundreds of such cards out of the 30,000 passing through her machine. Any Exchange regularly producing badly marked cards would receive the polite but icy wrath of Miss Whitehead together with an invitation for the Exchange Supervisor to visit the MATS Unit to see the additional work the badly marked cards could produce.

Sometimes an already damaged card would cause a 'wreck' i.e. a pile-up of cards anywhere along the card track, in which case the machine would stop because after the initial three feed cycles from empty, it was always testing for a card to appear just before the card receiver at the right time. In this case the Operator had to locate and carefully extract all of the damaged cards and then punch replacements with her hand punch. The inside of the machine was always hot and smelt of oil. The hand winding wheel at the front had to be used to raise the checking unit pins otherwise they could be easily damaged with the wreck knife (a long flat and thin bladed hook) in which case a two hour repair would be needed. If the machine carried on wrecking then the engineer had to be called to determine the cause and correct it. Sometimes an unwary operator merely pressed the start button when the machine unexpectedly came to a halt. In which case a further three cards would be driven into the already existing wreck site. If she had repeatedly done that the engineer had great difficulty in extracting the solid mass of cardboard within the punch stage and any tiny fragments not removed could cause further wrecking. The operator always had to reassemble the wrecked jigsaw of card fragments using sellotape, then decipher the pencil marks and punch up a substitute card.

Rev050812

All text © 2007 D.C.Adams